Why Choose BIOROTOR?

We know that managing a high-capacity sewage plant project can be a stressful, challenging task.

With BIOROTOR, you’ll always know exactly what to expect. Our system is innovatively different to others in process, design, and performance. It allows you to deliver state-of-the-art high capacity sewage systems without worrying about unwelcome surprises.

If what you need is a reliable, risk-free, and cost-effective system that goes beyond compliance, BIOROTOR is the best solution you can find.

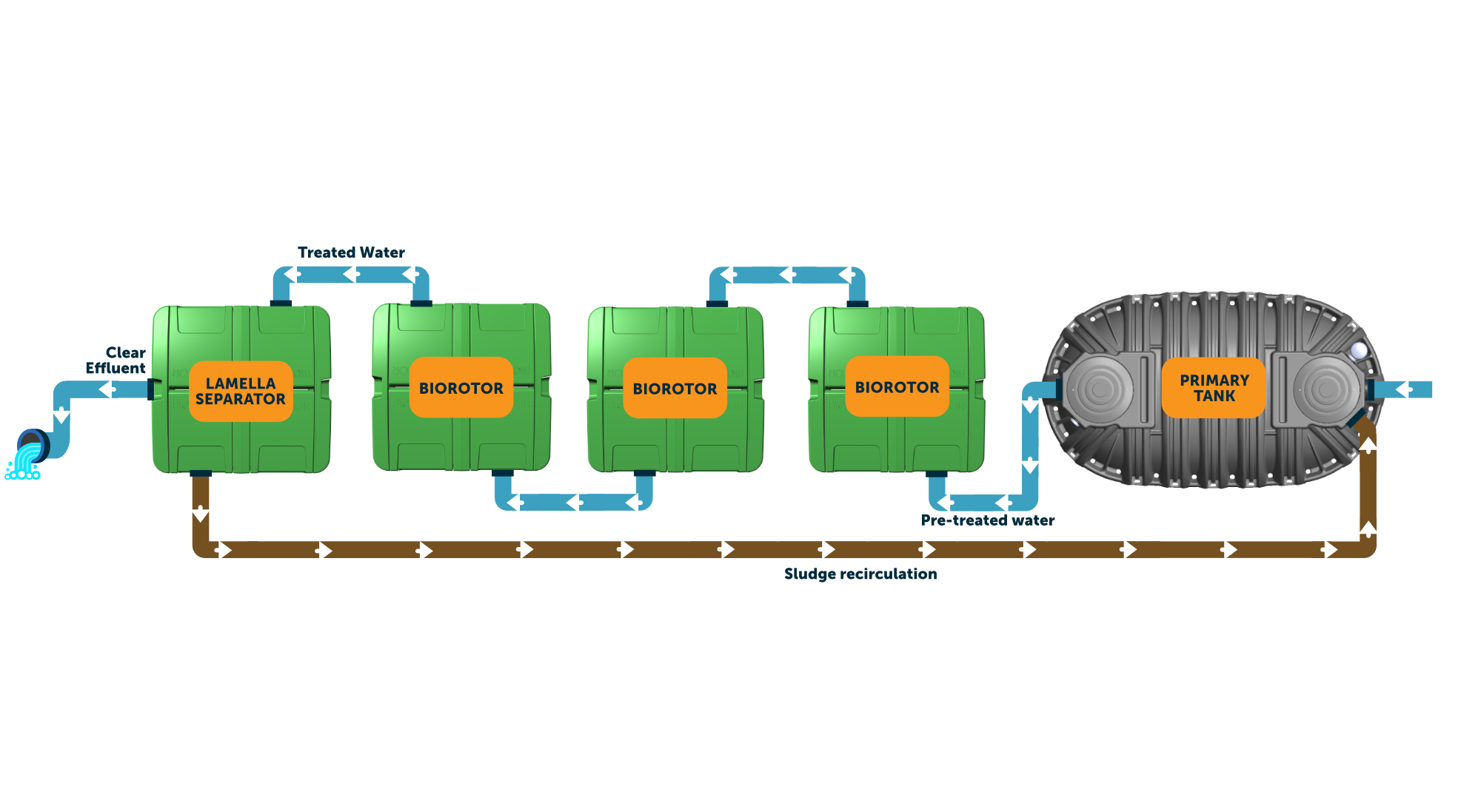

The BIOROTOR system was designed to be cost effective to transport, simple to handle, and quick and easy to install either above or below ground installations.

Our system is delivered with multiple integrated water inlets and outlets, and with all components already pre-assembled in the tanks.

The BIOROTOR modules require minimal maintenance and have excellent accessibility. The secure and lightweight lids enable direct access to all components for easy and fast maintenance.

Simplified on-site maintenance is a further benefit that lowers total costs of ownership while increasing overall reliability.

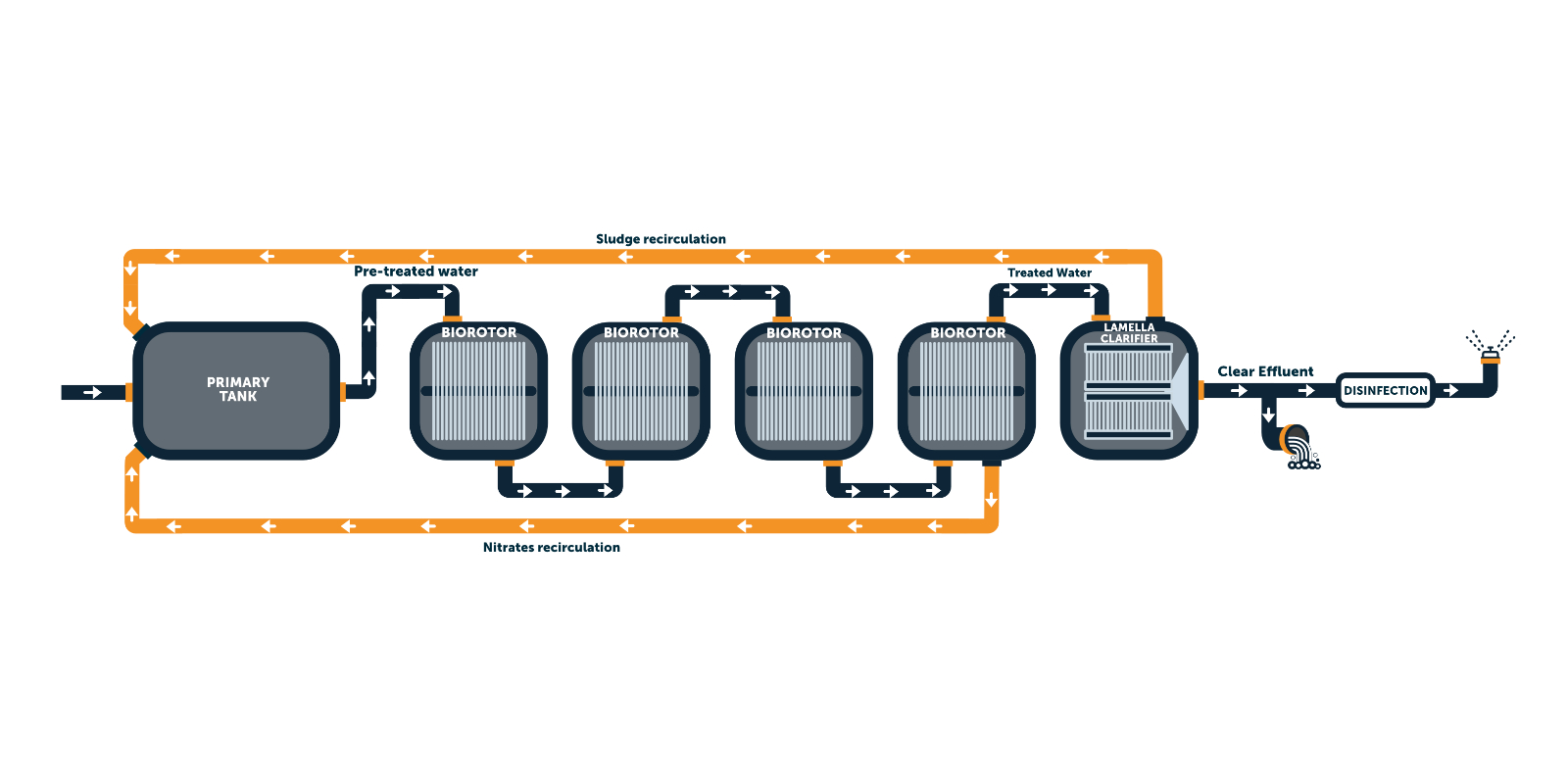

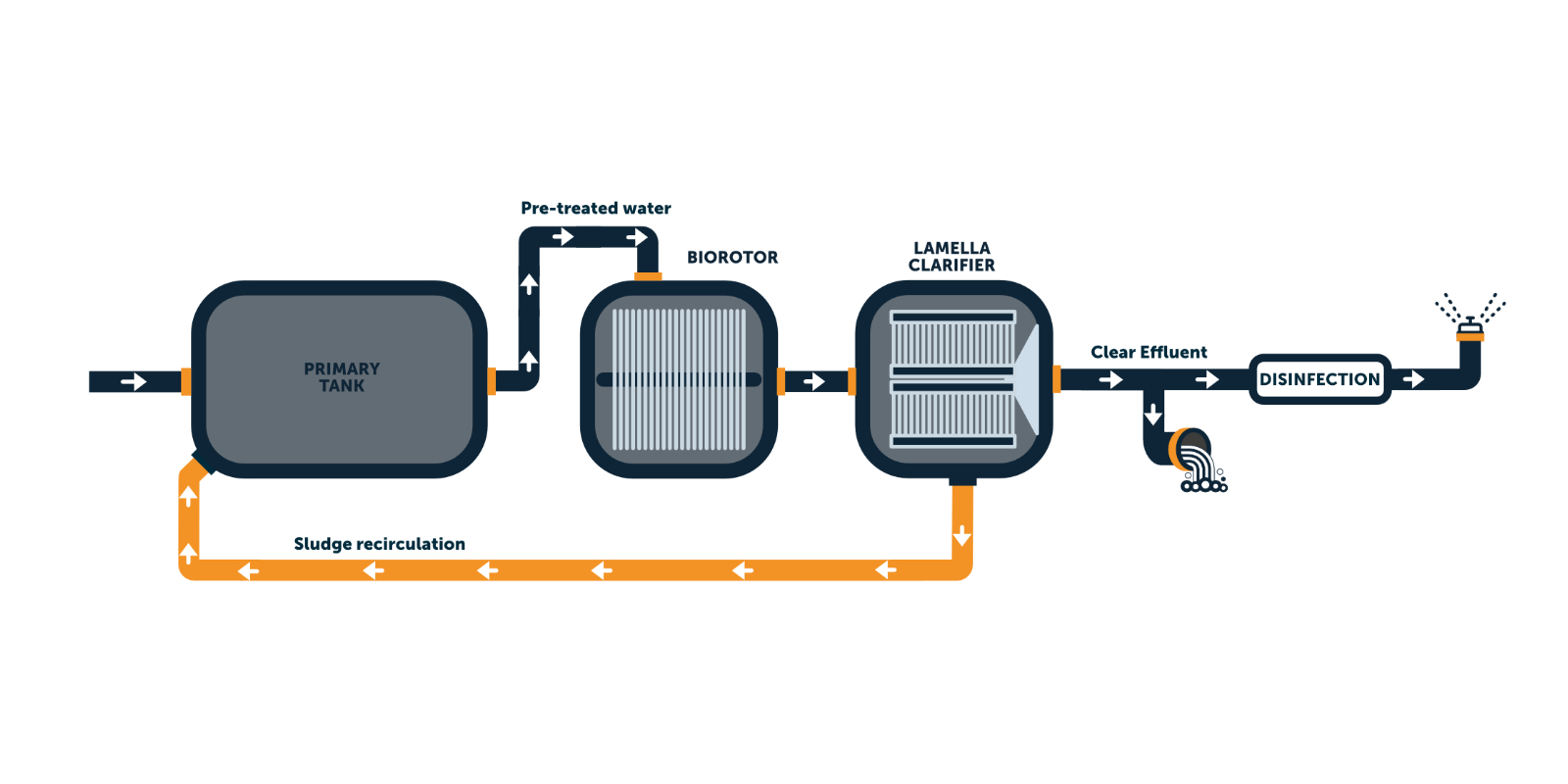

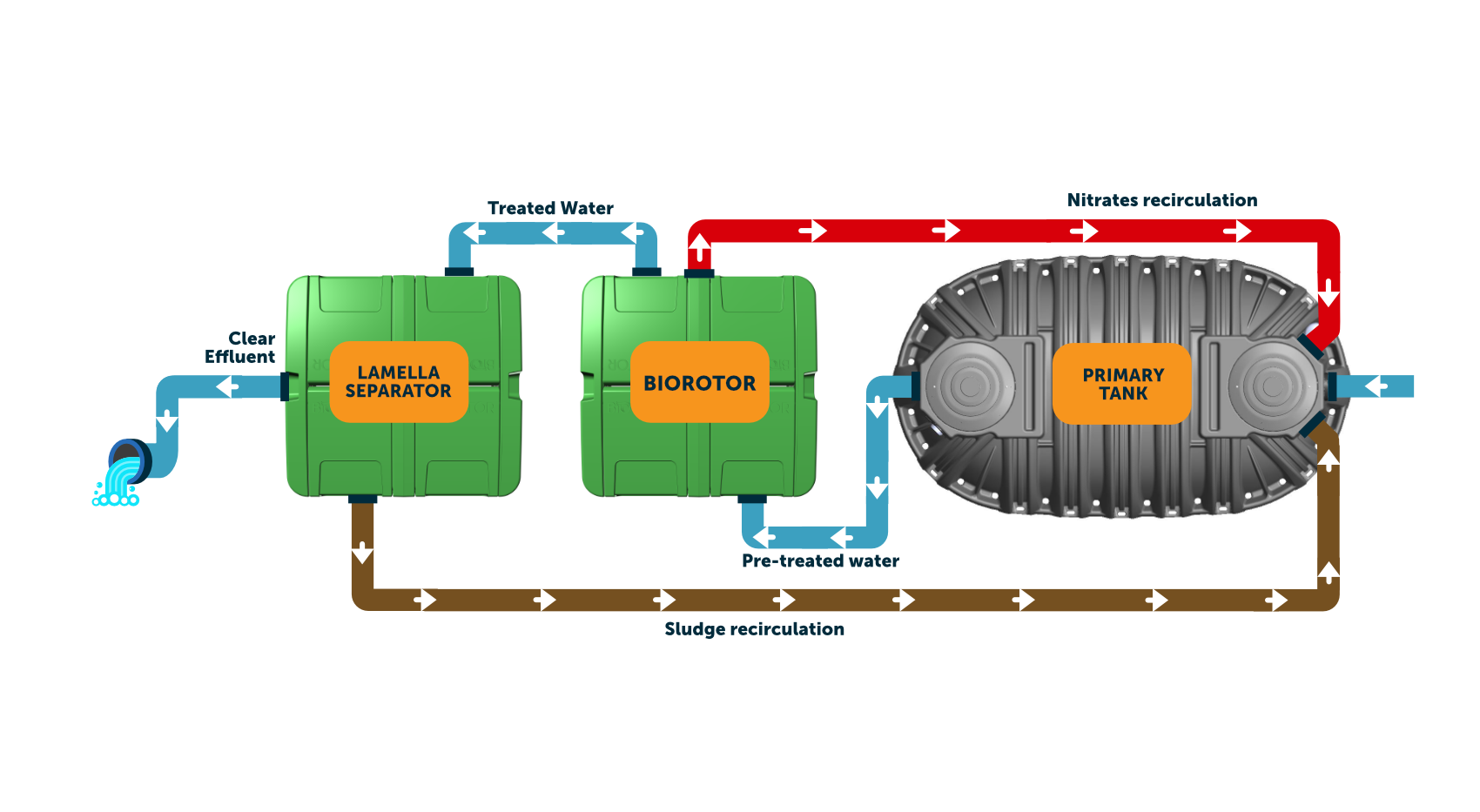

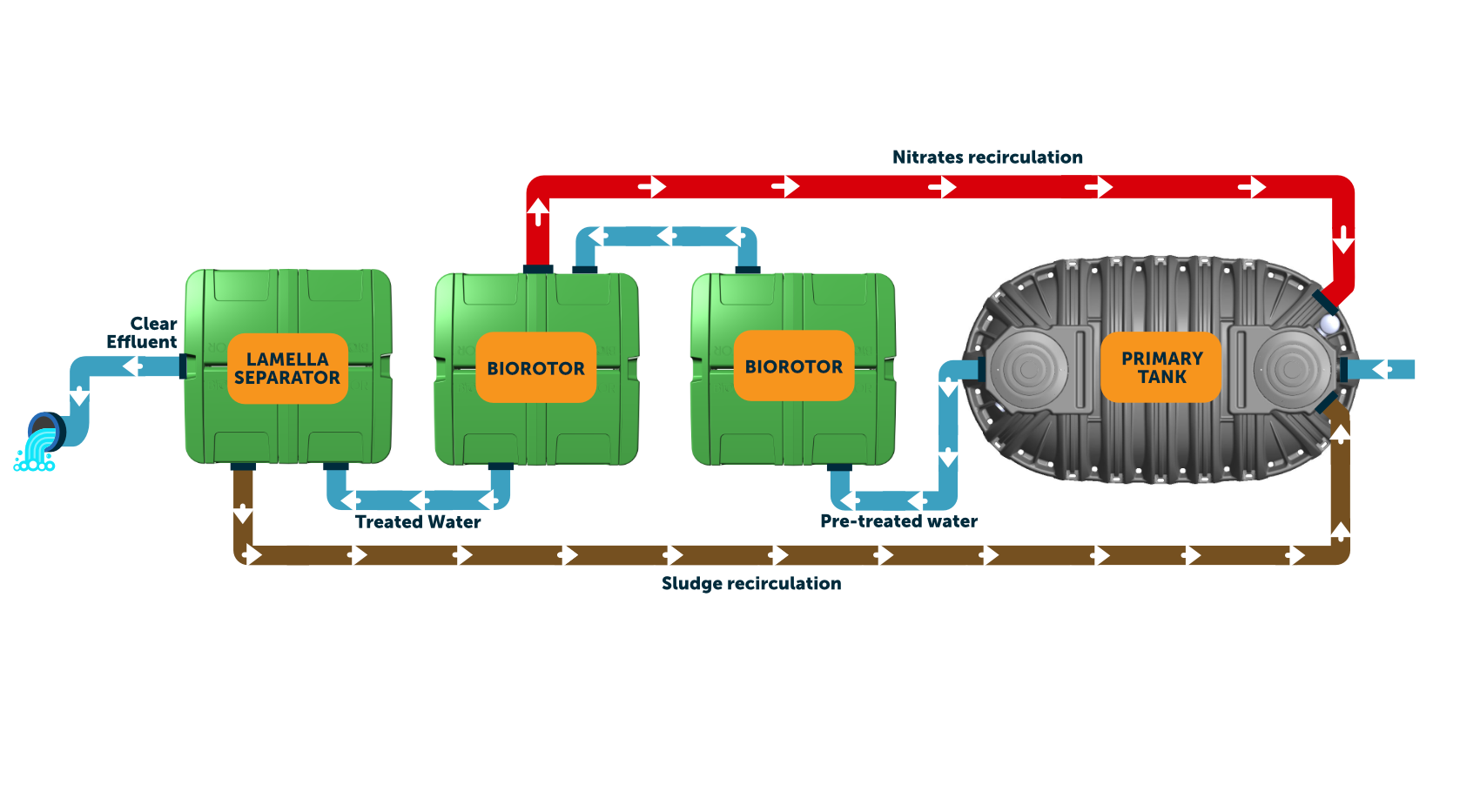

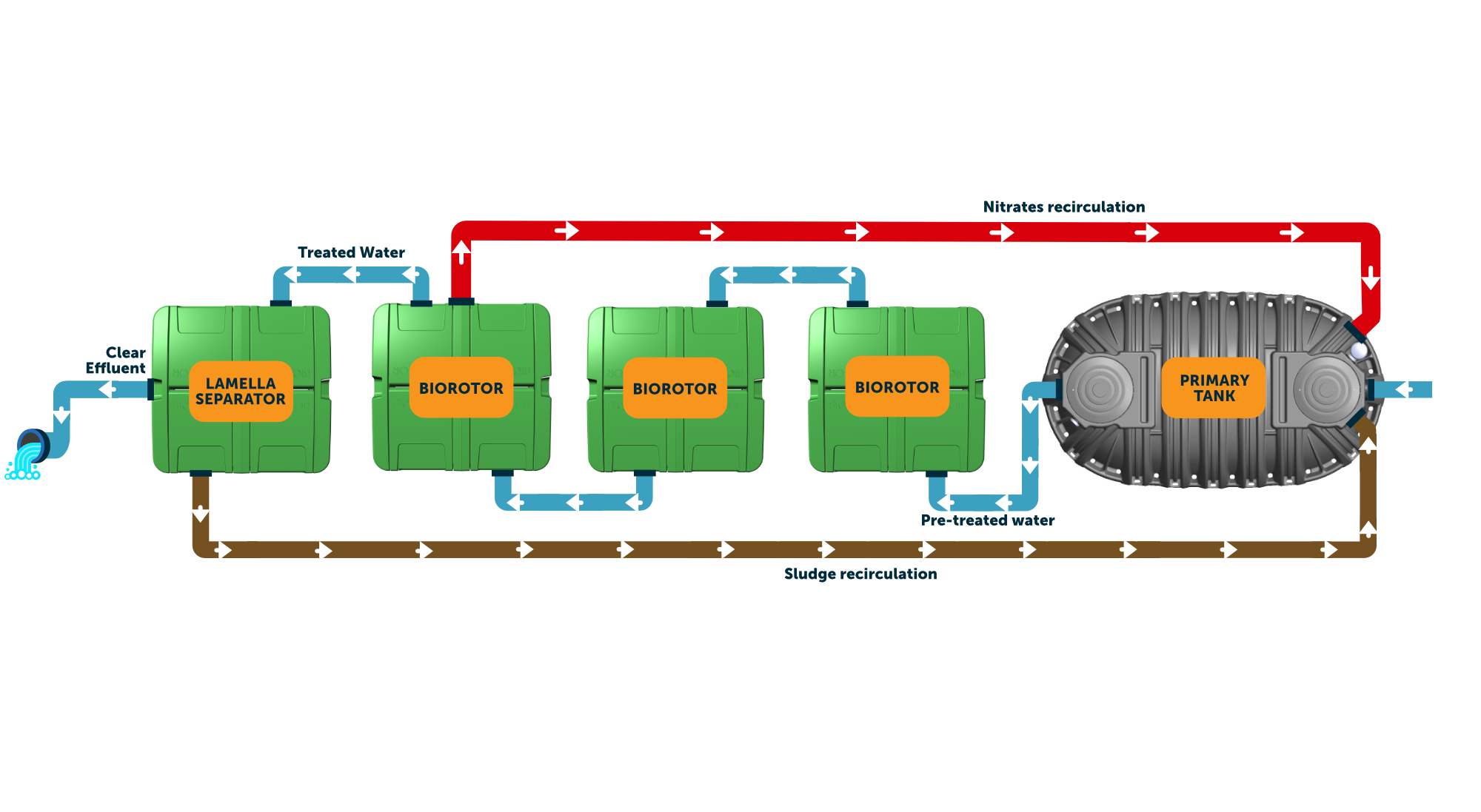

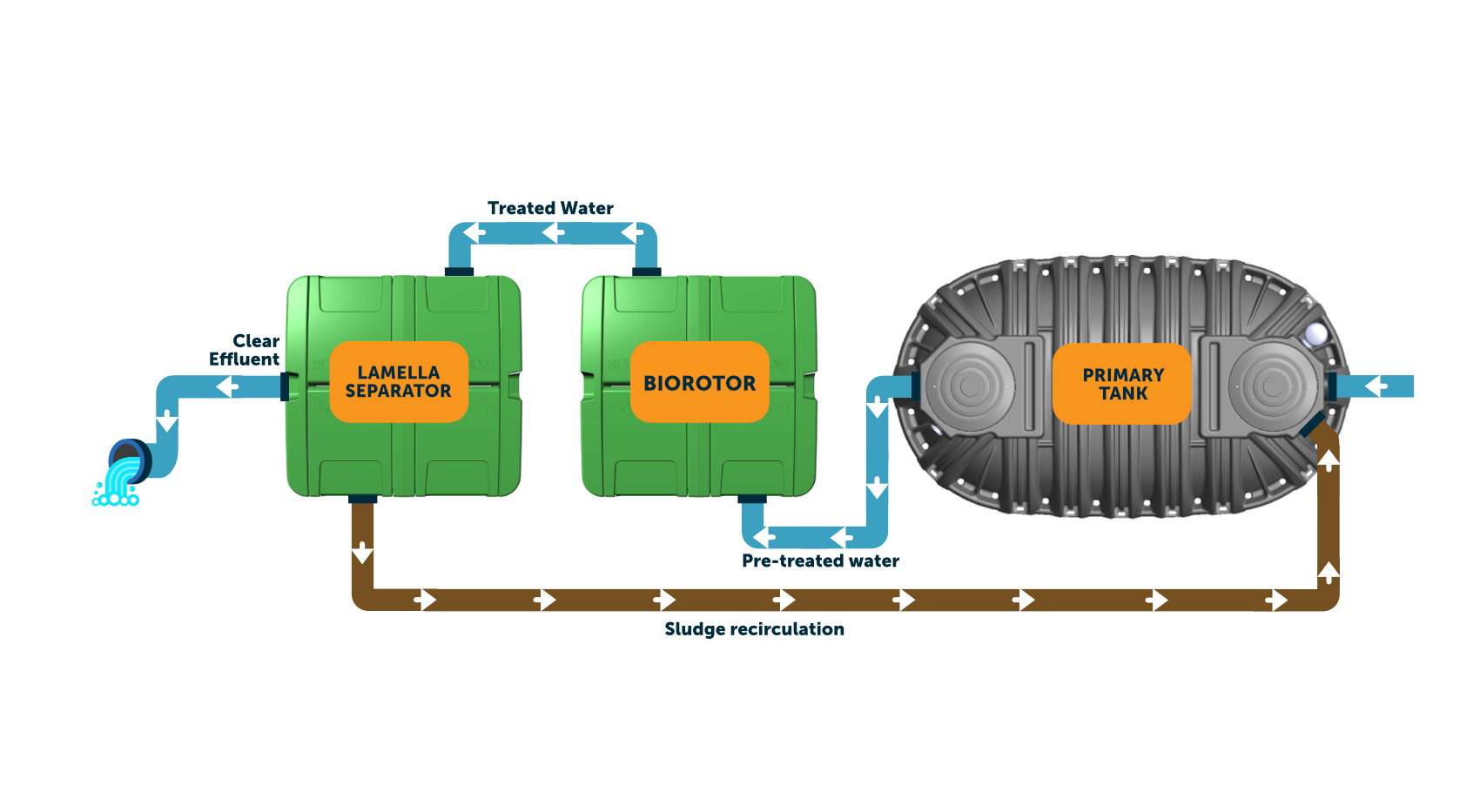

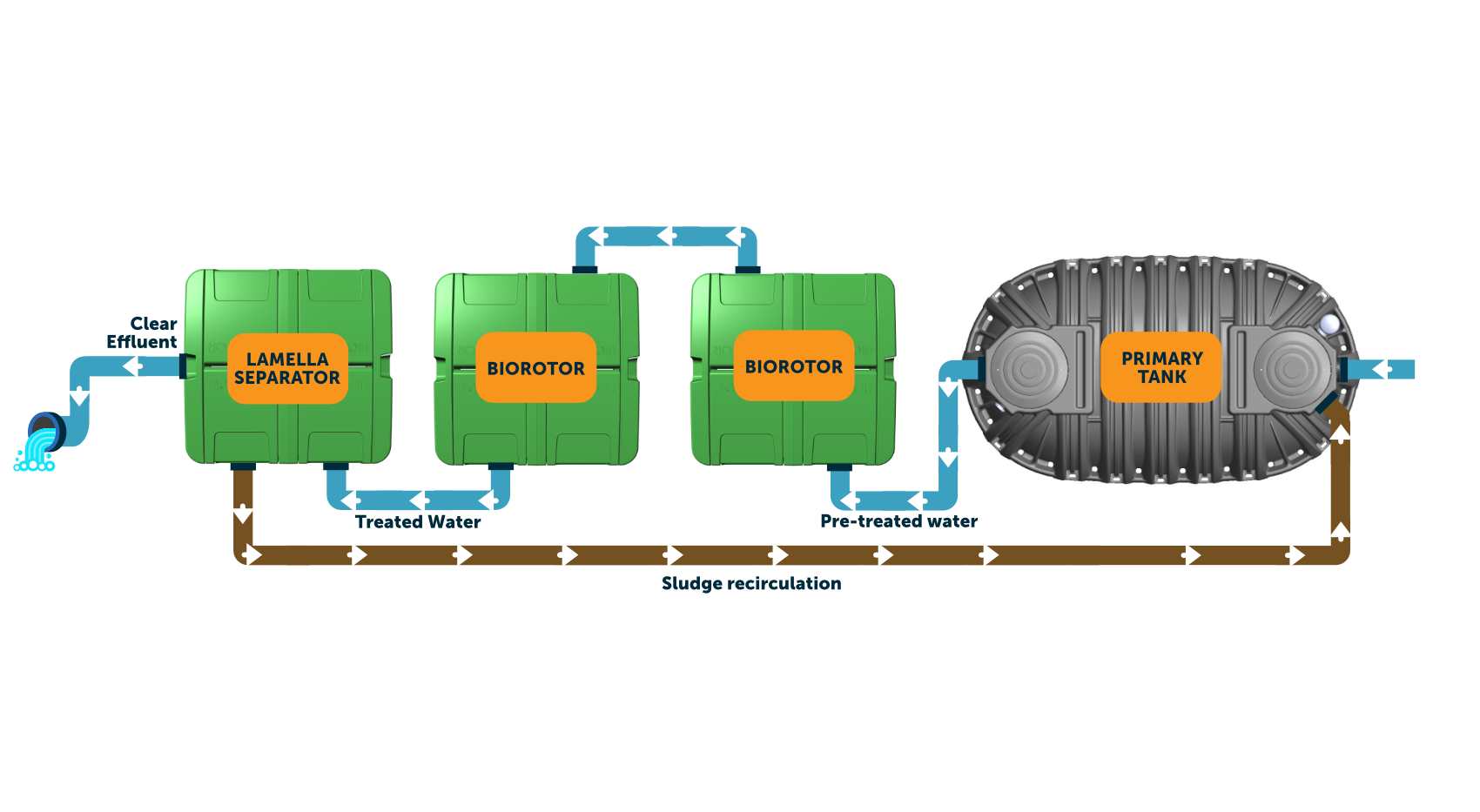

BIOROTOR is the first completely modular RBC system.

Whether you require controlled recirculation to effect denitrification, or a rotor-only retrofit solution for refurbishment projects in existing concrete structures, BIOROTOR offers a multitude of options.

The BIOROTOR system was designed to be cost effective to transport, simple to handle, and quick and easy to install either above or below ground installations.

Our system is delivered with multiple integrated water inlets and outlets, and with all components already pre-assembled in the tanks.

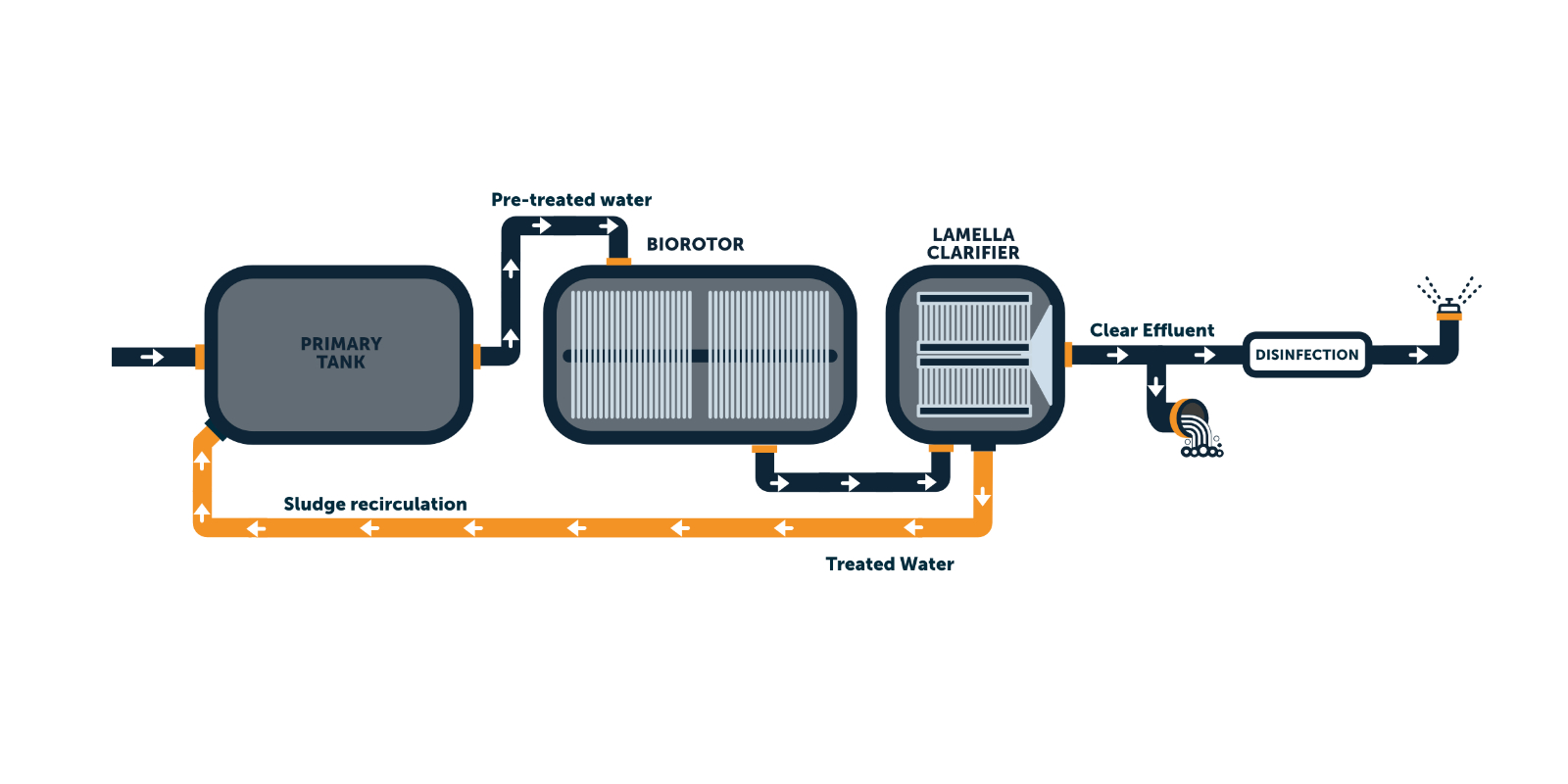

The BIOROTOR process complies with even the strictest effluent quality standards thanks to its versatile process configurations and efficient final settlement unit.

In standard configuration, it achieves the following effluent parameters :

BOD5 : 20mg/l

Suspended solids : 30mg/l

Ammonia : 20 mg/l

The BIOROTOR technology is based

on decades of worldwide RBC experience. It innovatively incorporates numerous patent pending processes, including a revolutionary gear drive system, improved water transfer buckets, and clog-resistant media.

What’s more, only robust, high-quality materials are used throughout the construction, guaranteeing a long-service life and making BIOROTOR the most robust and reliable system ever created.

The HDPE housing and accessories are made with a unique rotational moulding technique, using one-of-a-kind moulds.

BIOROTOR has a very unique ring gear drive system, where it’s no the motor that drives the shaft (large torque), but the outer disk (small torque). This ensures that a very small motor can be used.

Thanks to this very unique ring gear drive system, BIOROTOR has the lowest energy requirement per population equivalent compared to other treatment technologies.

In multiple configuration situations, each module is powered by its own engine. This allows to have a system where each motor can be driven by solar energy, which is an ideal solution for rural areas.

ENERGY CONSUMPTION OVER 10 YEARS IN KWH FOR A 600 PE INSTALLATION

BIOROTOR has a very unique ring gear drive system, where it’s no the motor that drives the shaft (large torque), but the outer disk (small torque). This ensures that a very small motor can be used.

Thanks to this very unique ring gear drive system, BIOROTOR has the lowest energy requirement per population equivalent compared to other treatment technologies.

In multiple configuration situations, each module is powered by its own engine. This allows to have a system where each motor can be driven by solar energy, which is an ideal solution for rural areas.

ENERGY CONSUMPTION OVER 5 YEARS IN KWH FOR A 600 PE INSTALLATION

ENERGY CONSUMPTION OVER 10 YEARS IN KWH FOR A 600 PE INSTALLATION